-

1st Floor, No.89 Maqian Road, Sanxiang Town, Zhongshan City

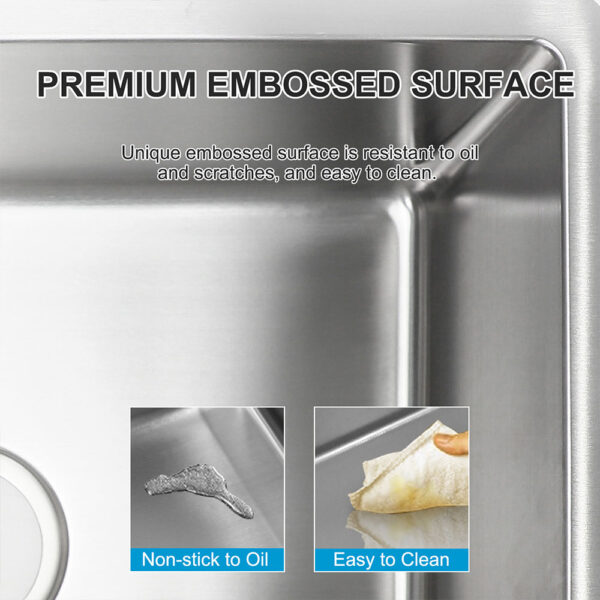

Embossed Stainless Steel Single Bowl Kitchen Sink Basin

the embossed stainless steel single bowl kitchen sink basin brings a deep, smooth washing space with a non stick surface that shrugs off oil, stains and light scratches for calmer daily cooking.

the embossed stainless steel single bowl kitchen sink basin is made for small but busy kitchens. the unique textured surface helps food and oil lift away easily, so you spend less time scrubbing after meals. its deep bowl handles pots, pans and fresh produce without splashing. straight walls and tight corners create extra usable space while keeping a modern look. paired with the included drainer and roll up rack, this sink turns even a compact counter into a clean, efficient prep and washing zone.

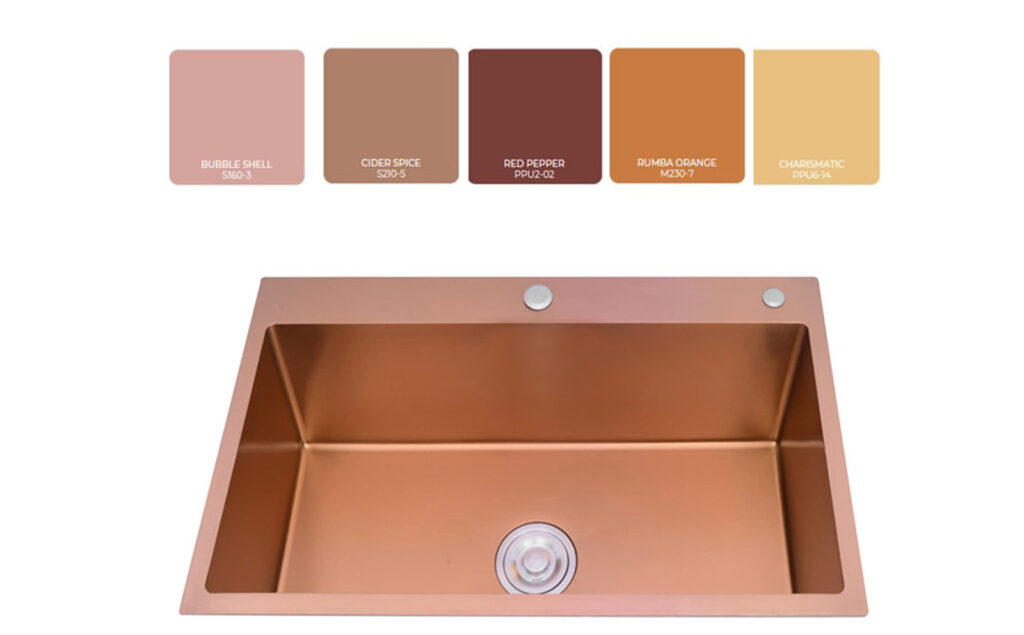

Color

We understand the importance of color in kitchen aesthetics. Therefore we offer a wide range of color options for our stainless steel sinks, allowing our clients to choose a finish that best aligns with their kitchen decor. Whether classic silver matte black, or warm copper we’ve got you covered.

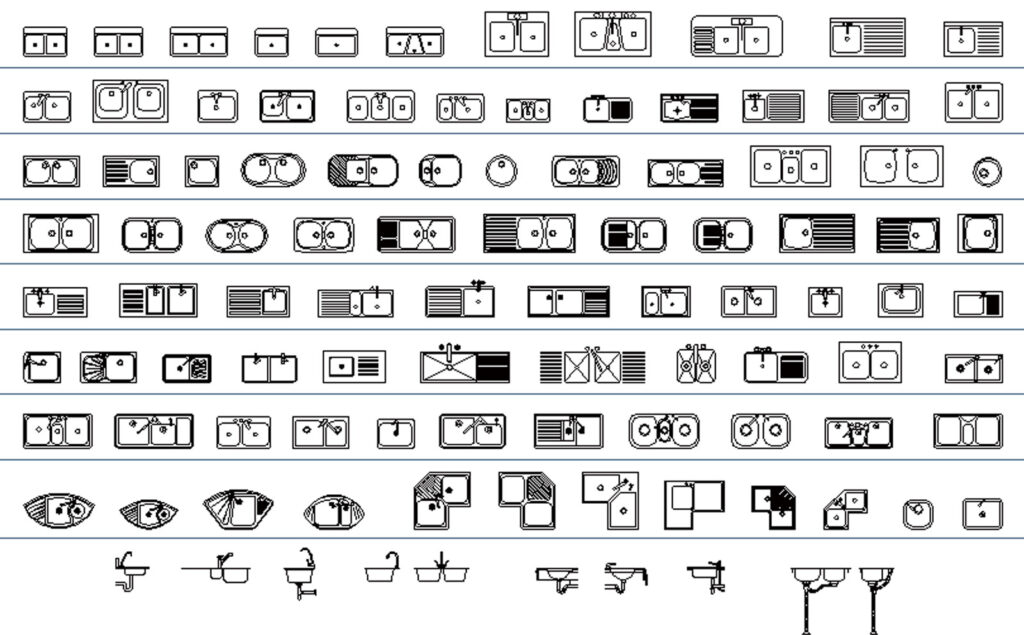

Size

Kitchen spaces can vary greatly in dimensions. We offer size customization to ensure our sinks fit seamlessly into your design. You provide the specifications, and our expert manufacturers will craft a sink to your exact measurements.

Design

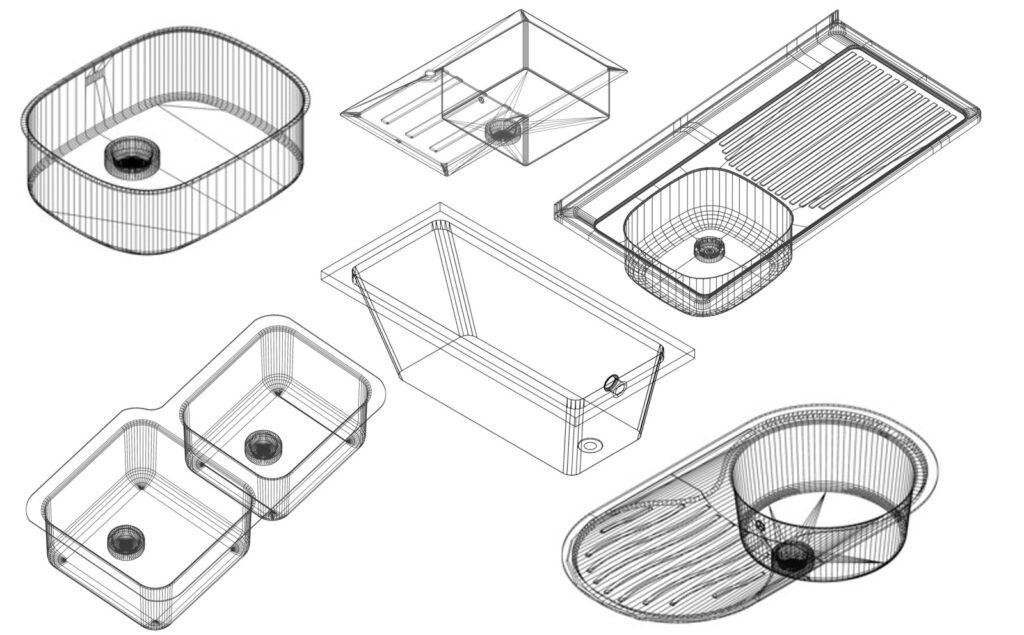

Design can drastically influence the functionality and appearance of a sink. Whether you prefer a single or double basin, rounded o sharp edges, or undermount or top mount installation, we can customize the design to meet your requirements.

Shape

A unique shape can transform a sink into a statement piece. We provide shape customization to help you achieve the look you desire. From classic rectangles to unique D-shapes, we can craft sinks in various shapes to enhance your kitchen’s aesthetic.

Logo

We offer logo customization for businesses that want to make a mark. Whether embossed, laser engraved, or etched. We can incorporate your logo onto our sinks, allowing you to promote your brand while providing top-quality products.

1

The cut sheets are in the desired sinkshape. Pressing sink is usually done bydeep drawing, where a punch presses thesheet into a forming die. The handmadesink is generally done by a bendingmachine, using a bending process to formthe shape.

2

These are welded together if the sink design requires multiple parts (like doublebasin sinks). This process is performed precisely to ensure a seamless look and watertight seal.

3

After forming and welding, the sink undergoes polishing. This process removes any blemishes from the forming and welding processes and gives the sink its characteristic shine.

4

A noise-reducing coating is often applied tothe underside of the sink. The coating helps to dampen the sound of running water and clattering dishes.

5

The last step in the process is a thorough quality inspection. Each sink individually checked for defects to ensureit meets high-quality standards.

6

Once approved, the sinks are carefully packaged to prevent any damage during transit and then shipped to customers.

7

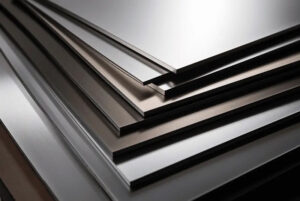

The process begins with the selection ofhigh-quality stainless steel. This metal ischosen for its durability, rust resistance.and ease of cleaning, making it the ideal

choice for kitchen sinks.

8

The stainless steel is then cut into sheets ofthe appropriate size. Precision in this step is crucial to ensure the final product has the correct dimensions.

Through our comprehensive after-sales support, we aim to sell you a product and build a lasting relationship based on trust and satisfaction. We are here to support you every step of the way, ensuring you get the most out of your investment in our stainless steel kitchen sinks.

Technical Support

Our highly skilled technicians are ready to assist you with any technical issues or queries about our stainless steel sinks. Whether it's installation advice or troubleshooting, we're here to help.

Warranty Service

We stand behind the quality of our products. That's why our stainless steel kitchen sinks have a full warranty. If you encounter any manufacturing defects or issues under normal usage, we will promptly address these issues by our warranty terms.

Parts and Repair

If a component of your stainless steel sink needs to be replaced, we can provide the necessary details at a fair price. We can also guide you through the repair process, ensuring your sink returns to optimal functioning as quickly as possible.

Customer Service

Our customer service team can answer any questions about our products, order status, delivery, etc. We strive to respond to all inquiries in a timely and professional manner. Your satisfaction is our highest priority.

Frequently Asked Questions

Why choose us for your stainless steel sinks?

Our sinks are made from premium quality 304 series stainless steel, featuring 18/10 chrome-nickel content, and are engineered in Germany to the highest standards of precision. The non-porous surface of our stainless steel prevents the buildup of dirt, bacteria, and microorganisms. Additionally, it naturally resists common household acids, marks, and stains from substances like coffee and various fruits and vegetables.

What is a stainless steel sink gauge?

The gauge of a sink indicates the thickness of the stainless steel. In this measurement system, a higher gauge number means thinner material. Most of our sinks are made from either 18 or 20 gauge stainless steel, ensuring they meet the highest standards and are tailored to the specific needs of our clients.

Can stainless steel sinks rust?

Stainless steel sinks do NOT rust, though they may sometimes appear to. The typical orange or red rust marks you see are usually caused by one of three sources: Steel wool pads used for cleaning Tin-coated steel cans or cast iron pots left in the sink while wet Iron deposits in the water These rust stains are not a sign of deterioration in your sink but are merely surface deposits. Scrubbing the stains with a mild cleanser or a metal cleaner like Flitz usually resolves the issue quickly. Remember to clean in the direction of the grain lines in the sink's finish.

What is the best gauge for a stainless steel sink?s?

We recommend 18 gauge as the optimal choice. While 16 gauge is thicker and adds extra weight, it’s a common misconception that thicker automatically means better. The 18 gauge stainless steel used in our sinks, as well as in other high-quality models, is just 0.5% thinner than 16 gauge but provides the premium durability and quality needed for a long-lasting sink.

What does Chrome-Nickel content mean?

Chrome-Nickel content refers to the percentage of chromium and nickel in the stainless steel of the sink. Chromium gives the steel its shine and durability, while nickel enhances its hardness and strength. An 18/10 stainless steel indicates that the sink contains 18% chromium and 10% nickel. All of our stainless steel collections feature 18/10 chrome-nickel content, ensuring superior durability and corrosion resistance.

Is sound deadening used in our stainless steel sinks?

Yes, we install the same high-quality sound deadening pads used by luxury automobile manufacturers on many of our stainless steel sink models.

Stainless Steel Sink Cleaning & Maintenance

How should I clean a stainless steel sink?

Cleaning a stainless steel sink is simple and doesn’t require harsh chemicals. Use a paste made from baking soda and water to clean the sink, then rinse with vinegar. Vinegar acts as a natural disinfectant and effectively removes hard water stains.

Can I use bleach to clean my stainless steel sink?

Bleach can stain and damage stainless steel, so it’s best to avoid using it. Don’t let dirty water or cleaning solution residues dry on your stainless steel sink, as this can dull the finish and cause permanent stains.

Can I use vinegar to clean my stainless steel sink?

Yes, mix equal parts vinegar and water in a spray bottle for easy use. You can spritz this solution to disinfect your kitchen sink, countertops, or any areas where you’d typically use bleach but prefer a food-safe option. To neutralize the vinegar smell, simply rinse the sink with soapy water afterward.

How can I remove hard water spots?

We recommend using a glass cleaner or a 50% vinegar solution mixed with water, which you can find at hardware stores. Avoid using table vinegar, as it has a lower concentration and may not be as effective.

How can I make my sink shiny?

Enhance the shine of your sink by using any eco-friendly cleaning products.

Why should I dry my stainless steel sink after rinsing?

Tap water contains dissolved minerals and salts that can be left behind when the water evaporates, creating spots similar to those you see on a car after a wash. Drying your sink after rinsing prevents these spots from forming. If you notice hard water deposits, use a little white vinegar to remove them. Afterward, rinse and dry the sink to maintain its shine.

Stainless Steel Sink Installation & Repair

What is the best type of kitchen sink installation?

The best sink installation type depends on your routine, available space, and style preferences.

Do stainless steel sinks come with pre-drilled faucet holes?

Yes, all of our stainless steel sinks include at least one pre-drilled faucet hole, and some models feature 3 to 5 pre-drilled holes for faucets and accessories.

What are the stains or residue at the bottom of my sink?

Multicolored stains or residue at the bottom of your sink are usually caused by minerals in your water or salts from water softeners. These stains can typically be removed with eco-friendly cleaning products. Be sure to clean in the direction of the grain lines, rinse thoroughly, and dry the sink.

Can stainless steel sinks be restored or refinished?

Yes, stainless steel sinks can be restored with deep cleaning treatments and specialized maintenance products. Steel polishers are effective for bringing back the shine. Be sure to follow the instructions carefully and always clean and polish in the direction of the brushed finish.

How do I remove paint from my stainless steel sink?

Dampen a cloth with water and apply scratch-free household sink bleach to it. Gently rub the cloth in slow, circular motions on the painted area for 30 seconds. Rinse the bleach off with room temperature water and allow the sink to air-dry.

What accessories can I use with my stainless steel sink?

We offer a variety of custom-fitted grids to protect the bottom of your stainless steel sink. Avoid using rubber-coated mats, as they may cause discoloration over time. Additionally, be cautious with wet sponges or cleaning materials left on the sink for extended periods, as they can stain the sink’s surface.

Stainless Steel Sinks Manufacturer

Leading Chinese stainless steel sink maker for kitchen, bathroom, bar and RV; premium single & double bowls, OEM/ODM services for clients and brands worldwide!

Quick Links

Products

Contact